Forklift General Awareness Training Course

Providing forklift operators and pedestrians with practical forklift safety training minimizes the risk of accidents and injuries to drivers and those around them.

Course description

Traliant’s Forklift General Awareness training is a 35-minute course designed for both forklift operators and pedestrians who work in the vicinity of forklifts and covers the fundamental principles of safely operating and working around powered industrial trucks and forklifts.

This course can enhance the employer's training and increase awareness when combined with the hands-on forklift and site hazard training mandated by the Occupational Safety and Health Administration (OSHA).

ONLINE TRAINING

Forklift General Awareness Training Course

Forklift general awareness covers these topics and more:

- Powered Industrial Trucks (PIT)

- The different types of forklifts

- Employer training requirements

- How to be aware of pedestrian traffic

- Proper usage of ramps and grades

- Hazards of operating a PIT in enclosed and hazardous area

KEY FEATURES

Why you'll love our training

It’s time to embrace a new era of online training with a valued partner who will ensure seamless implementation, along with a learning experience your employees will truly enjoy.

Course administration

Traliant makes it simple to roll out training to your workplace and provide technical support directly to your employees at no additional cost.

Course customizations

Tailor courses to include your logo, relevant policies, workplace images, and more. Traliant can even customize the course with scenarios that take place in your own workplace environment.

Translations

Training is available in English, Spanish and is supported in over 100 languages.

What to consider when choosing the most effective forklift awareness training

- Prevent accidents and injuries: Forklifts can be dangerous machines if they are not operated safely. Training helps to reduce the risk of accidents and injuries by ensuring that both operators and pedestrians are aware of the hazards.

- Create a safer workplace: Training helps to create a safer workplace environment for everyone.

- Comply with OSHA regulations: The Occupational Safety and Health Administration (OSHA) mandates forklift training for operators. Awareness training can complement OSHA's requirements and enhance the overall safety program.

- Empower employees: Training provides employees with the knowledge and skills they need to operate forklifts safely or to work safely around them.

- Strengthen your organization's commitment to safety: Training demonstrates the company's commitment to creating a safe working environment.

- Reduce the risk of accidents, injuries, and property damage: Training helps to minimize the risk of forklift accidents, which can result in injuries to operators, pedestrians, and damage to property.

- Tip-overs: Forklifts can tip over if they are overloaded, driven too fast, or operated on uneven surfaces.

- Collisions: Forklifts can collide with pedestrians, other vehicles, or objects.

- Falling loads: Loads can fall from forklifts if they are not properly secured.

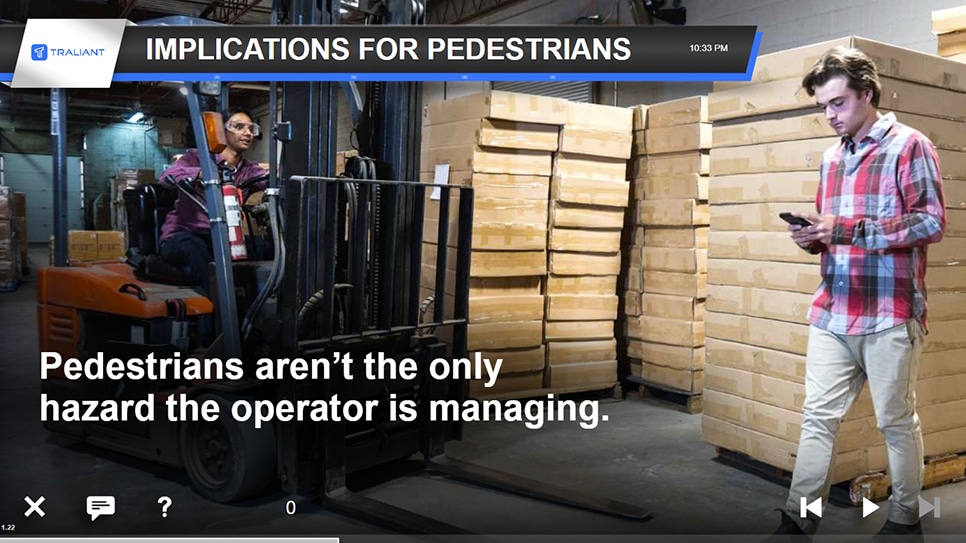

- Pedestrian hazards: Pedestrians can be struck by forklifts if they are not aware of the forklift's movements.

- Wear a seatbelt: Always wear a seatbelt when operating a forklift.

- Inspect the forklift before use: Check the forklift for any damage or defects before operating it.

- Operate at a safe speed: Obey speed limits and adjust your speed based on conditions.

- Use caution on ramps and grades: Slow down and be extra cautious when operating on ramps or grades.

- Be aware of pedestrians: Always be aware of pedestrians and other vehicles in the area.

- Be aware of their surroundings: Pay attention to the movements of forklifts.

- Maintain a safe distance: Stay clear of forklifts, especially when they are in operation.

- Make eye contact with the operator: Before crossing a forklift's path, make eye contact with the operator to ensure they see you.

- Wear high-visibility clothing: Wear high-visibility clothing to make yourself more visible to forklift operators.

- OSHA requirements: Forklift operator training is mandated by OSHA. Training must include both theoretical and practical components.

- Specific forklift types: Training should be specific to the type of forklift that the operator will be using.

- Workplace-specific hazards: Training should address the specific hazards present in the workplace, such as narrow aisles, uneven surfaces, and pedestrian traffic.