Electrical Safety Training for Employees and Businesses

Using appropriate safety measures when working with electricity reduces workplace accidents, injuries, fatalities and fires.

Course description

Traliant’s Electrical Safety training is a 30-minute course that explains the basics around electrical safety and the common risks related to power lines, cords, power tools and sockets. Additionally, the course covers Lockout/Tagout procedures, the dangers of working with electricity and best practices to keep workers and others safe.

This course aligns with the Occupational Safety and Health Administration’s (OSHA) general industry programs and focuses on the fundamental principles of electricity and its associated hazards and danger points.

ONLINE TRAINING

Electrical Safety Training for Employees and Businesses

Electrical Safety covers these topics and more:

- Current, resistance, voltage, conductors, insulators and grounding

- Types of electrical hazards

- Electrical protection methods

- Purpose of the energy control program

- Hazardous energy sources and methods necessary for energy control

- Primary causes of injury from hazardous energy

- Lockout/Tagout

- Steps to properly control hazardous energy when servicing equipment

KEY FEATURES

Why you'll love our training

It’s time to embrace a new era of online training with a valued partner who will ensure seamless implementation, along with a learning experience your employees will truly enjoy.

Course administration

Traliant makes it simple to roll out training to your workplace and provide technical support directly to your employees at no additional cost.

Course customizations

Tailor courses to include your logo, relevant policies, workplace images, and more. Traliant can even customize the course with scenarios that take place in your own workplace environment.

Translations

Training is available in English, Spanish and is supported in over 100 languages.

What to consider when choosing the most effective electrical safety training

- Protect employee health and safety: Electricity can be extremely dangerous. Training helps to ensure that employees understand the risks and know how to protect themselves.

- Comply with OSHA regulations: The Occupational Safety and Health Administration (OSHA) has specific regulations related to electrical safety. Training helps to ensure that organizations are complying with these regulations.

- Reduce the risk of accidents and injuries: Electrical accidents can lead to burns, electrocution, fires, and other serious injuries. Training helps to prevent these accidents.

- Empower employees: Training provides employees with the knowledge and skills they need to make informed decisions about their safety when working with electricity.

- Strengthen your organization's commitment to safety: Training demonstrates the company's commitment to providing a safe working environment and to protecting the health of its employees.

- Reduce the risk of accidents and injuries: When employees are aware of the risks and know how to work safely with electricity, they are less likely to be injured.

- Current: The flow of electrical charge.

- Voltage: The electrical potential difference between two points.

- Resistance: The opposition to the flow of electrical current.

- Conductors: Materials that allow electricity to flow easily, such as copper and aluminum.

- Insulators: Materials that resist the flow of electricity, such as rubber and plastic.

- Grounding: A system that provides a path for electrical current to flow safely to the earth in the event of a fault.

- Wiring deficiencies: Damaged or improperly wired equipment can create a risk of electrical shock.

- Improper grounding: If equipment is not properly grounded, it can become energized, posing a shock hazard.

- Overloaded circuits: When too many appliances or devices are connected to a circuit, it can overload, causing overheating and potential fire hazards.

- Exposed wires: Exposed wires can create a shock hazard.

- Wet conditions: Working with electricity in wet conditions can increase the risk of electrical shock.

- Ground Fault Circuit Interrupters (GFCIs): GFCIs detect small changes in current flow and interrupt the electrical circuit to prevent shock.

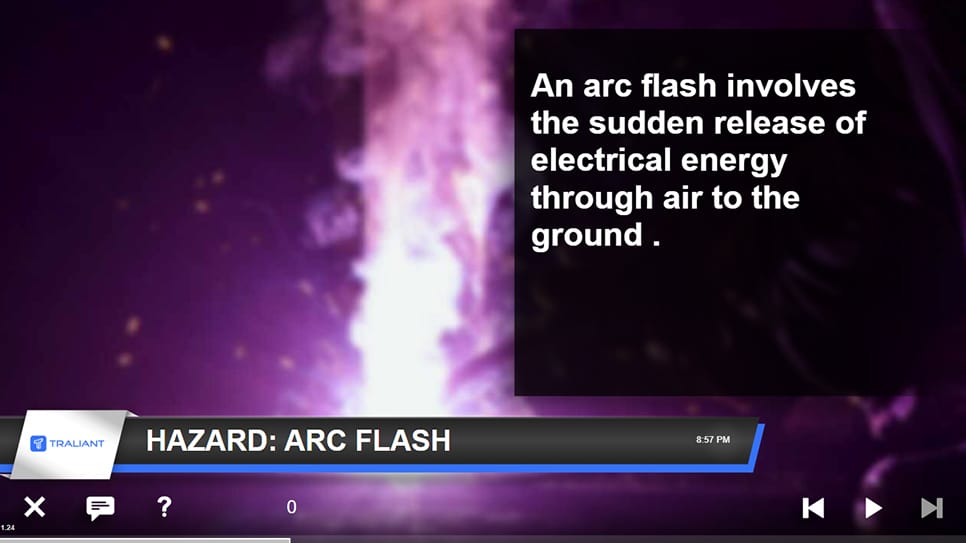

- Arc Flash Protection: Arc flash protection helps to minimize the risk of burns and other injuries from arc flashes.

- Lockout/Tagout: Lockout/tagout procedures are designed to ensure that electrical equipment is de-energized and isolated before it is worked on.

- Conduct electrical hazard assessments: Identify the electrical hazards present in the workplace.

- Develop electrical safety plans: Create procedures for addressing and controlling electrical hazards.

- Provide electrical safety training: Train employees on the hazards of electricity, safe work practices, and emergency procedures.

- Ensure that equipment is properly maintained: Conduct regular inspections of electrical equipment to ensure that it is in good working order.

- Develop an emergency response plan: Establish procedures for responding to electrical emergencies.